Lubricants are the lifeblood of machines. They are critical for keeping assets healthy and productive. And much like a blood test, analyzing lubricants can alert us to potentially life-threatening problems before it's too late.

If improving reliability or lowering maintenance costs is your goal, it pays to look at your lubricants and lubrication practices carefully and holistically. Are lubrication staff properly trained? Are lubricants kept clean enough? Are oil change or regrease intervals set properly? Are recent machine failures related to lubrication?

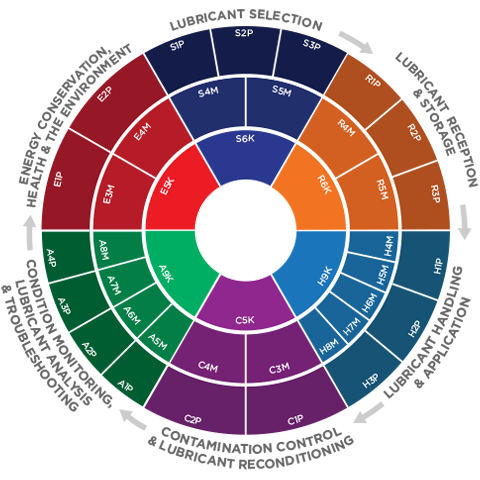

Answering these questions (and more) is the beginning of Lubrication Program Development (LPD). Noria experts use this holistic, three-phase process to help customers identify gaps in their lubrication programs and make a prioritized plan for improvements.

You can build a lubrication program that:

- Reduces downtime

- Promotes reliability culture

- Minimizes costs

- Establishes KPIs to measure progress

- Is streamlined for efficiency

- Delivers significant ROI

Your 3-Phase Plan to a Better Bottom Line

1. Ascend Assessment

Get a customized roadmap for quick wins and long-term success, along with training, KPIs, and a detailed report to help you cost-justify improvements.

2. Engineering Design

Noria experts survey your lubricated assets, collecting all the data needed to deliver comprehensive procedures along with lubricant and hardware recommendations.

3. Implementation

Noria facilitates the vendor selection and procurement process to outfit your program with equipment and hardware you need to achieve your reliability and maintenance goals.

Powered by

"In the short time since implementation we have already achieved 53% more uptime over previous years and that continues to improve."

Scotty Lippert, Clopay Corporation

Customer Wins

Learn how you can drive success with lubrication

Failures Reduced at Simmons Feed

Simmons Feed Ingredient Plant in Southwest City, MO, was experiencing a rash of equipment failures until Noria brought training and lubrication program improvements to the plant.

Training Success at Kimberly-Clark

Noria training helped Kimberly-Clark’s Fullerton Mill reduce lube consumption, oil losses have dropped by 30%, machine delays have decreased and the mill has fewer breakdowns.

Sinclair Saves Millions in Maintenance Costs

Onsite training and Lubrication Program Development helped transform the Sinclair Wyoming Refinery into an industry leader in lubrication. The refinery shifted to a proactive maintenance approach, significantly impacting its operations and bottom line.

Frequently Asked Questions

Lubrication Program Development (LPD) is divided into three phases, each one is listed with its average timeline below:

Phase I: Ascend Assessment

1 week

Phase II: Engineering Design

6 - 8 weeks

Phase III: Implementation

1 - 2 years